Got a balky steering system on your trusty Economy 1614? This comprehensive guide provides a step-by-step approach to restoring your tractor's steering, covering everything from simple fixes to more involved repairs and potential upgrades. Whether you're a seasoned mechanic or a weekend warrior, we'll empower you to tackle this project with confidence. For additional tractor parts, check out this helpful resource.

Giving Your Steering a Once-Over: The Initial Inspection

Before you reach for your tools, a thorough inspection is crucial. This will pinpoint the problem areas and guide your repair strategy.

Assess Steering Play: Grab the steering wheel and check for excessive play or looseness. Significant wobble indicates worn components within the steering system. *How much play is too much? A good rule of thumb is less than one inch of movement. * This initial check will help to determine the extent of the issue.

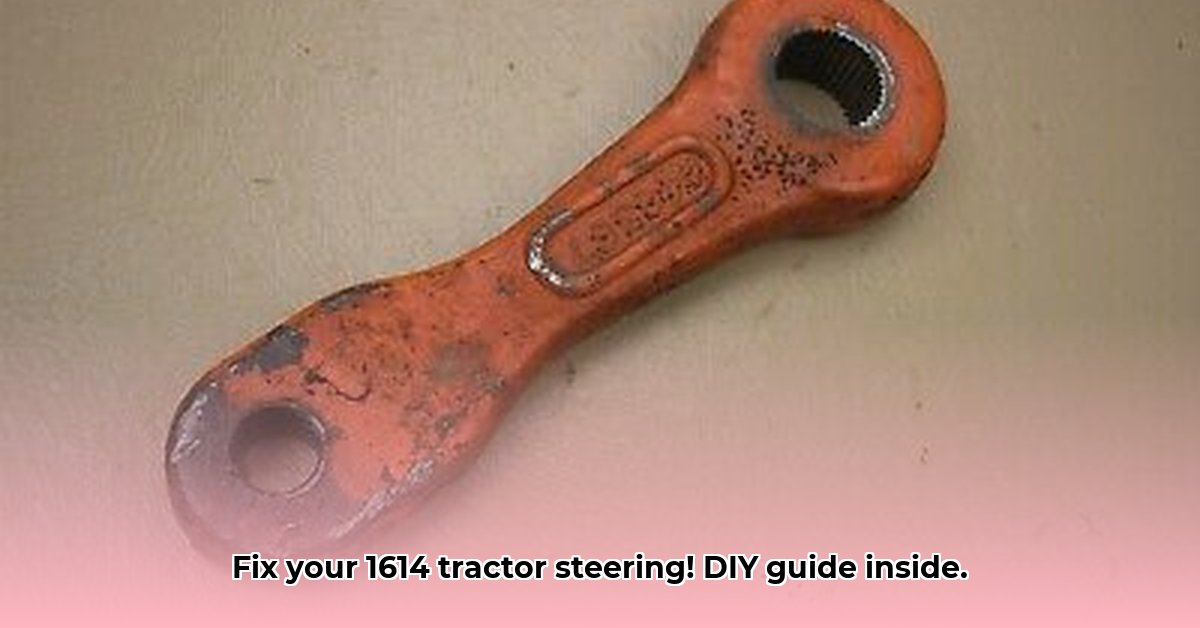

Examine the Linkage: Carefully inspect the linkages connecting your steering wheel to the steering box. Look for any bent, broken, or severely corroded components. Loose or damaged linkages hinder precise steering and can lead to instability. A visual inspection combined with a wiggle test on each component will expose any problems.

Check for Leaks: Look for hydraulic fluid leaks around the steering box. A leak often signals a worn-out seal needing replacement. Fluid leaks can quickly deplete your tractor's hydraulic fluid levels causing steering loss.

Inspect the Bearings: Check the bearings. They should rotate smoothly and freely, with minimal play. Any roughness, stiffness, or excessive play signifies a potential problem that needs immediate attention. Stiff bearings may indicate a need for lubrication or possible replacement.

Remember to document your findings with photographs or sketches. This visual record is invaluable when reassembling your steering gear.

Taking it Apart: Disassembly and Component Check

Disassembling the steering gear requires basic hand tools, but some specialty tools may be needed based on your findings from the inspection. Always disconnect the battery before you start working!

Secure the Tractor: Park your tractor on level ground, engage the parking brake, and chock the wheels. Safety is paramount.

Remove the Steering Wheel: This typically involves unscrewing a nut or bolt. Take photos as you progress to aid in reassembly.

Disconnect the Linkages: Carefully disconnect the linkages from the steering box, taking note of their positioning. Detailed photographic documentation is essential.

Remove the Steering Box: The method for removing the steering box varies depending on your specific tractor model. Refer to your tractor's service manual for detailed instructions.

Disassemble the Steering Box: Once removed, meticulously disassemble the steering box, keeping track of all parts and their positions using photographs and diagrams.

Clean and Inspect Components: Thoroughly clean each part and carefully inspect it for wear, damage, or rust. This close analysis is key to understanding the extent of repairs needed.

Meticulously label and organize all parts during disassembly to make reassembly easier and less frustrating.

Repair or Replace? Weighing Your Options

After the inspection and disassembly, you'll decide whether to repair or replace your steering components.

Repair: Repairing is generally more cost effective but requires more time and effort. Parts availability may also be an issue for older tractors.

Replacement: Replacing the entire steering box is faster but more expensive. This route ensures optimal reliability and performance, eliminating potential lingering issues from a patched-up repair.

Putting it Back Together: Reassembly and Testing

Reassembly follows the disassembly process in reverse order. Your photographs and your tractor's service manual will be invaluable.

Steering Box Installation: Install the repaired or replaced steering box securely.

Reconnect Linkages: Attach the linkages. Precise alignment here is crucial for smooth steering operation.

Reinstall Steering Wheel: Securely reattach the steering wheel.

Ground Test: Start the tractor and carefully test the steering for responsiveness, play, and any binding.

Fine Tuning: Make minor adjustments as needed to ensure perfect steering action.

Always refer to your tractor's service manual for specific instructions and torque specifications.

Keeping it Healthy: Preventative Maintenance

Regular maintenance is crucial for preventing future steering problems.

- Regularly inspect for leaks, excessive play, and wear.

- Follow your tractor's lubrication schedule.

- Addressing minor issues promptly prevents them from escalating into major problems.

By following these steps, you can restore your Economy 1614's steering to optimal condition, ensuring many more years of reliable service. Remember, tackling this project takes patience and care, but the satisfaction of returning your tractor to peak functionality is well worth the effort.